Garstin 1871 MEET THE MAKER

Behind the scenes of handcrafting the perfect leather satchel

This week we sat with the team at Garstin 1871, to talk all things craft, brand and heritage.

SGB: So Garstin 1871 has a rich history but has been dormant for a long time, why was it the right time to bring the brand back to life?

Garstin 1871: Great question, you are correct Garstin 1871 has been around since Edwardian times as the name suggests. We believe that in these times of fast fashion and throw away culture the world is slowly wakening up to a buy fewer but better culture. And what better way to embrace this than with a classic brand such as Garstin 1871. We simply wanted to create bags how they used to be made.

SGB: The name Garstin 1871 and its logo evoke a heritage but modern feel, is this deliberate?

Garstin 1871: Well, Garstin 1871 is a heritage brand. With a rich history, so the feeling of the brand is certainly there to evoke a time when things were made better and you could trust the product which you were buying to do the job intended and do it for a long time. We redesigned the logo because Garstin had had many different logos over its 150 years. We wanted a logo that felt like you had seen it before, so was familiar but also felt modern enough to grab your attention.

SGB: What three words best describe Garstin 1871?

Sue: Quality, durable, stylish.

SGB: What did it take to bring Garstin 1871 back to life?

Garstin 1871: Reviving a classic brand that hasn't been around for many years takes a lot of effort and is not as easy as we first thought. We first researched the market to see if there was appetite for beautifully made leather goods, which there undoubtedly is. We then needed to make sure the product was the right product. We knew we had to pay homage to the original ethos of Garstin, which was British quality with timeless style. We also wanted to make bags that are quintessentially British. There are other satchels made in the Britain, but the quality we felt could be vastly approved on. We then of course needed to design and make those products. It then required, a website, packaging, photography and a whole heap of other stuff in the back end that I won't bore you with.

SGB: Have there been any major hurdles that you’ve had to overcome in order to get Garstin 1871 up and running?

Garstin 1871: Achieving the perfect satchel was quite a challenge, especially one that is made for the modern world. But this was part of the challenge we enjoyed. The choice of leather was a real challenge too. We support British manufacturing but to make the finest satchel we could we decided on using Italian leather. British leather is great and some of the best in the world but that is mainly for saddlery. The leather for satchels is very different, so one of the hurdles was how long it took the leather to reach the UK from Italy. This put us back quite a lot. The other challenge with making in the UK is pricing. Of course you can buy cheaper when a product is made in the Pacific Rim or in fact Eastern Europe due to wages but we believe in the skilled crafts men and women of Britain to produce a bag that will, if treated well, last a lifetime and in fact get better with age.

SGB: So quality is a driving force behind the brand?

Garstin 1871: It is indeed, the first thought we had was we wanted to create heirloom pieces, satchels that you could hand down to your children and even your grandchildren. We imagined that if you found a Garstin 1871 satchel in a Parisian flea market in 100 years time you would be drawn to its patina and style, it would still be fit for purpose even with all it has been through. Garstin started in 1871 their ethos was British quality with style so quality will always be a driver for Garstin 1871. The world is full of products that break too easily or are just absolutely useless. That is one of the reasons we offer a lifetime promise. If anything fails on a Garstin product we will do all we can to fix the problem, obviously unless it has been dragged behind a tractor down a country road.

We are also transparent about where our source materials come from and where our bags are made. The leather we use comes from a small Italian tannery in Tuscany that is family owned and make quite possibly the finest leather for bags. Our suede comes from Charles F Stead in Leeds. The metalware comes from Abbey Foundry that has been suppling the royal family for decades. And we make our satchels in small batches in a small atelier in the rolling hills of Gloucestershire.

SGB: Does Garstin 1871 have any other British brands that is aspires to be like?

Garstin 1871: We don't aspire to be like anyone else, we want to be the make the best Garstin 1871 products we can make. Saying that Britain is full of beautiful and sometimes a little eccentric accessory brands that may not be as famous globally as its Italian or French peers but are equally as desirable. Britain does though have a global reputation for quality but we believe that in the modern world British brands haven't shouted as loud (marketing spend) as those European brands. It is no coincidence that LMVH which is owned by the world's richest man and include Louis Vuitton as one of their brands spent €9.5 billion on marketing in 2022.

SGB: Can you talk us through the design and manufacturing process of your products?

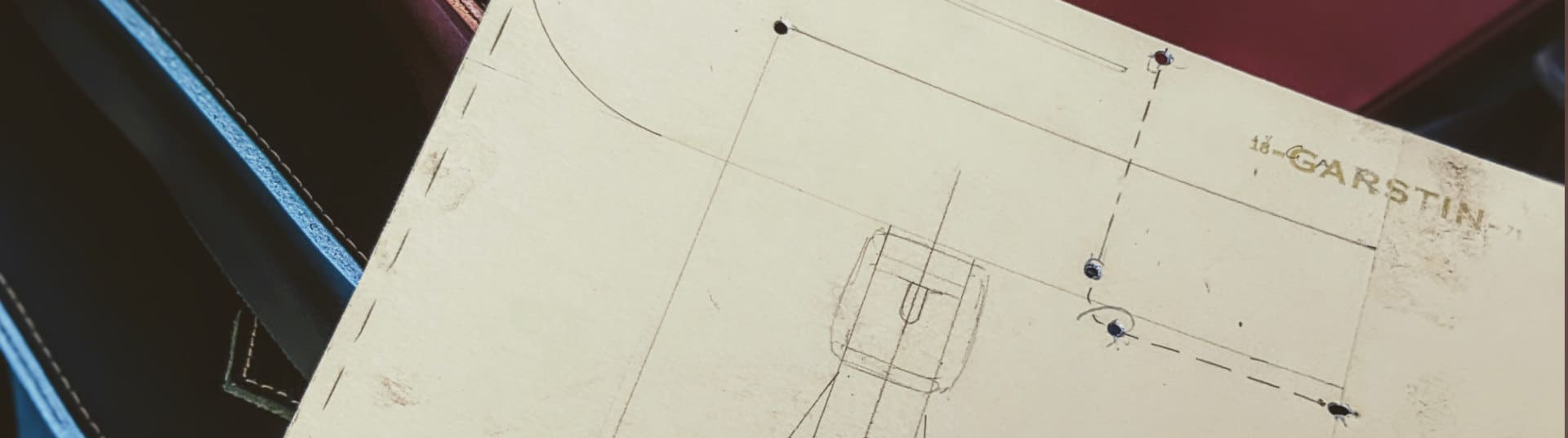

Garstin 1817: We have worked very closely with a traditional bag maker to design the first satchel. We did many initial drawings after looking at some old satchels from the 50's and then modernised them a touch so they would work as a modern bag, whether for work or an everyday handbag. The great thing about satchels are that they are unisex, they look classic and a touch old school when a man carries one but stylish when a woman does. So after we agreed on a satchel design the bag makers began to create the templates for each of the panels as you can see in the picture above. Once we are happy with the 'blueprint' we create 'knives', these are the tools that cut the leather to precise measurements so each satchel is pretty identical, they will never be identical due to the nature of being handmade. After each section is cut it is then all about stitching them together. This is done by hand on a Willcox & Gibbs machine, this is very precise work and takes real patience to get right, any mistake means the panel is ruined, and as the leather we use is rather expensive it is a worrying time for us. Once the satchel has been crafted and constructed the final touch is buffing the leather edges to finish off the satchel, this is of course all done by hand.

SGB: What is you favourite part of the designing / production process?

Garstin 1871: For us the whole process is pretty magical from conception to holding a satchel, knowing that from an idea a beautiful item has been created that can be used and enjoyed. But if you asked the bag maker, I know they love the final buffing of the edges, they say it is rather pleasing and who are we to disagree.

SGB: The bags do look beautiful, and after holding one we can honestly say they are the real deal but one thing that stands out is the colours of the leather. Was this a conscious choice of colour palette?

Garstin 1871: Absolutely, La Perla Azzurra, the tannery in Italy has a set amount of colours so we went through them very rigorously. If the truth be told, that took us a couple of weeks to decide which colours to proceed with. We wanted them to feel like a set, just for aesthetic reasons and they had to feel both classic without feeling dowdy and modern without feeling brash. I think we have achieved that.

SGB: The world is talking about sustainability more and more, so is it important Garstin 1871?

Garstin 1871: We truly believe in building a brand that is as sustainable as possible. No brand should ignore how they affect the planet. Some would say you should stop using leather, but leather is a by product from the meat industry and if it wasn't used in leather goods it would simply go to waste. When the world stops eating meat, we would certainly stop using leather but it is essential to use everything we can to be as sustainable as possible. The leather from La Perla only comes from certified 100% European stock, their reputation is second to none when it comes to quality. But more than the raw materials, we want people to buy better but fewer things. This is paramount to helping save the planet. We should all have a buy once attitude and really think about what we want and what we need.

SGB: With that in mind how is sustainability implemented within your brand?

Garstin 1871: We only make in small batches, this is to minimise waste. When you make in larger batches we feel mistakes can come into the process, which means waste. You should probably only need to buy one satchel in your life so we think you should buy the best satchel you can. With that in mind it is natural to think about the durability of the item you are purchasing. If the quality is poor you may end up having to buy the same item again. Whether or not the item is purported as being 'sustainable', something that breaks quickly is bad for the environment no matter how it is made or what it is made from. When buying a Garstin 1871 satchel you are reducing your footprint by investing in an item which lasts a lifetime.

SGB: Thank you Garstin 1871 team for taking the time out of your day but finally is there anything exciting in the pipeline for Garstin 1871?

Garstin 1871: Making bags of such high quality and in small batches is rather costly and finding funding to expand the range quickly is difficult. But we do have many ideas, we are determined to make bags that people will love to have in their life and that are useful too. We have started to design a classic Gladstone or Doctor bag which is another icon of British design just like the satchel.